Company

- Home /

- Company

OFFICINE MECCANICHE GALLI: QUALITY MANUFACTURE

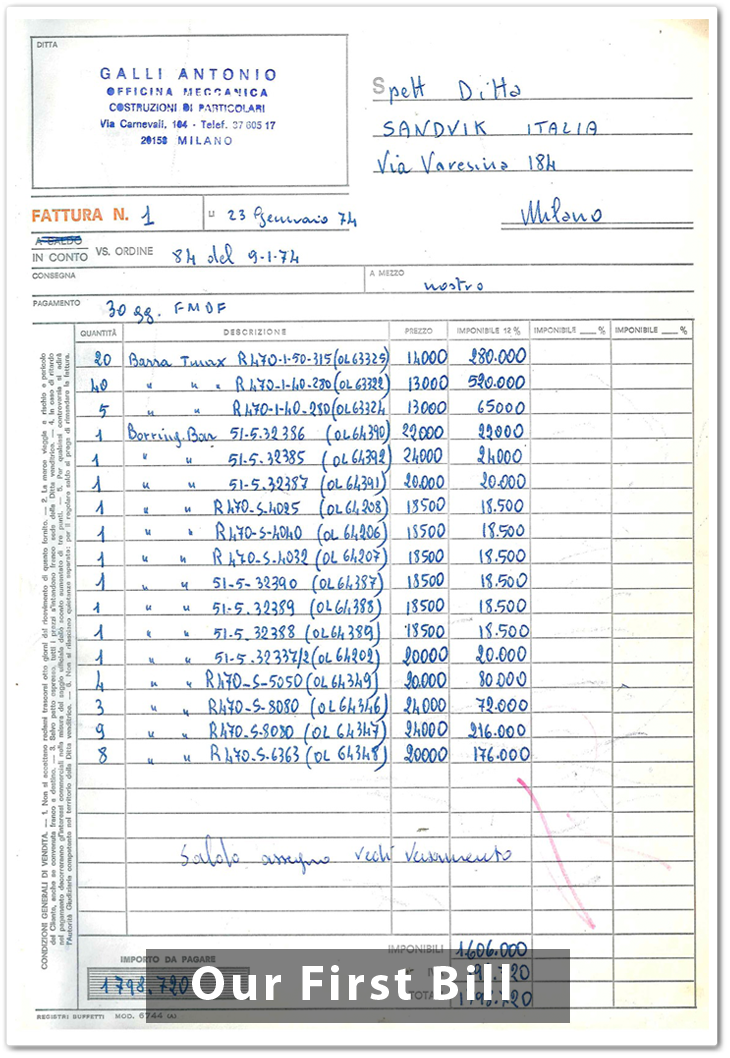

Officine Meccaniche Galli has been founded in 1974 by Antonio Galli and the core business of the company was the tolling manufacture of special boring bars.

In 1986 with the purchase of the first CNC machine, TORNIO COMEC CNC OLIVETTI, the manufacturing capabilities improved significantly in terms of both quality and flexibility.

In 1988 the company also acquired the first CNC milling machine, MIKRON WF51 and, even remaining bound to the tolling production of special tools, the product portfolio increased in size and variety.

At the beginning nineties as the son, Alessandro Galli, started to have an important role in the family business, the company design a new Vision based on a constant grow in production capabilities and on a continues investment in new manufacturing technology and quality standards.

During the last 15 years the company has focused his core business in the production of special and high complex tools like: Special milling cuter with 40 inserts for automotive sector, special Drill with a length up to 1,5 m, Drill heads, under cut, HFR, front pilot cutter body for deep holes, High Feed Milling, Speed Finishing Milling.

In addition, at the beginning of the year 2000 the company has acquired the first Wire Electric Discharge Machining that enables them to work carbide and produce special inserts for mechanical industry. With this new technology was possible to produce special tools with very special inserts

During the same year after installing the CAM NX they were also able to program the first 5-Axes Machining Centre

In order to increase quality and improve the productivity, in 2005, the production capability increased installing a Turning and Milling 5-Axes Machining Centre MAZAK INTEGREX that allows the company to execute in a single step-up the 5-Axes milling and turning operations.

Officine meccaniche Galli, in 2006, has decided to increase his own quality standards reaching the ISO 9001 certification with SGS. This certification opens the door to more demanding markets approaching high standard international customers.

The company is exporting highly complex tools like for example feed out bar and High feed reamer (HFR with hydraulic movement), in countries like Germany, UK, North America and China.

Officine meccaniche Galli is constantly investing in new technology approaching different market with extremely high quality standards. After serving for many years the communication sector, automotive and aeronautic market, with the acquisition of the new MIKRON HPM 450 with pallet magazine, they entered in the Medical sector becoming a production toller for big lots of

Machining medical components, in particular with regard to instruments for orthopaedic use and plastic inserts for knee,

The more regularly employed materials include: stainless steel, aluminium, titanium and plastic.